Packaging machinery complete parts or all of the packaging process. The process includes bags forming, film wrappings, products filling, bags sealing etc. Auto packing machine provides manufacturers and factories with efficient packaging methods and the product storage and transportation protections.

We Samsonpac are is one of packaging machine companies in China. We are committed to developing impactful and innovative packaging solutions for our clients. We offer options for improved efficiency, properly calibrated and supported machines, which can decrease packaging materials use and improve packaging speeds.

The term packaging machine is a wide-ranging mix of machines covering many industries and it protect products from transportation and storage. The packaging process including filling, wrapping, sealing and packaging process, and its associated processes before and after, such as cleaning, drying, sterilization, stacking, demolition, including Printing, labeling, measurement, and other auxiliary processes.

The machines listed below are common packaging machines and the machines can vary greatly in size or packaging machine design, but still perform the same basic functions. All machines are involved in the process of packaging, transporting, storing and selling products.

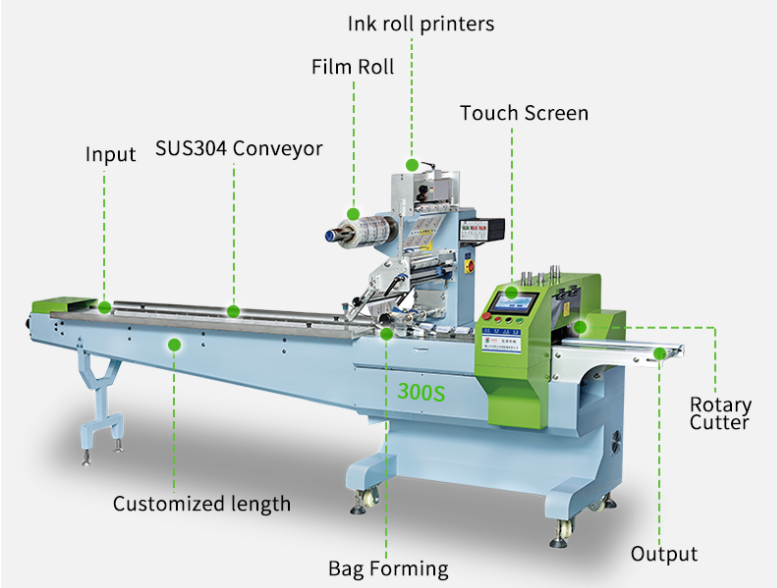

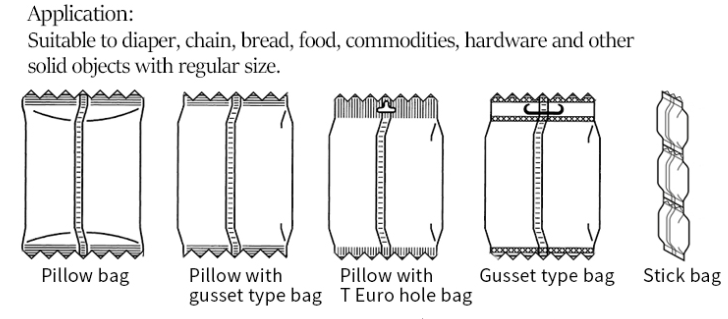

Two common types of horizontal machines, flow wrapper and stand-up pouch bag machines, producing the bag horizontally, and the product falls vertically into it.

It is a flexible solution to packaging because it incorporates all stages of production automatically. This makes the whole process of packaging quicker. It can fill and seal solid, liquid, or dry products without any problems. Take Full Servo Horizontal Flow Packing Machine SS-450S/500S Manufacturer as an example.

● All control in onetouch screen, user-friendly andeasy operation

● Empty bag prevention, no product no bag

● Product cutting prevention, machine will stop once cutter cuts the product

● Memory function, can store99 groups of package parameters (product position, packing speed, bag length)

● No limit for product length

Applications:

Blister packaging machines seal products in a cavity, usually with a paper backing or aluminum or film seal. It covers thermoforming and cold forming, plug assist deep forming for complicate shape, vacuum/blow/plug forming, etc. Blister packing machines are special machines that are used as unit-dose packaging for tablets, capsules, etc.

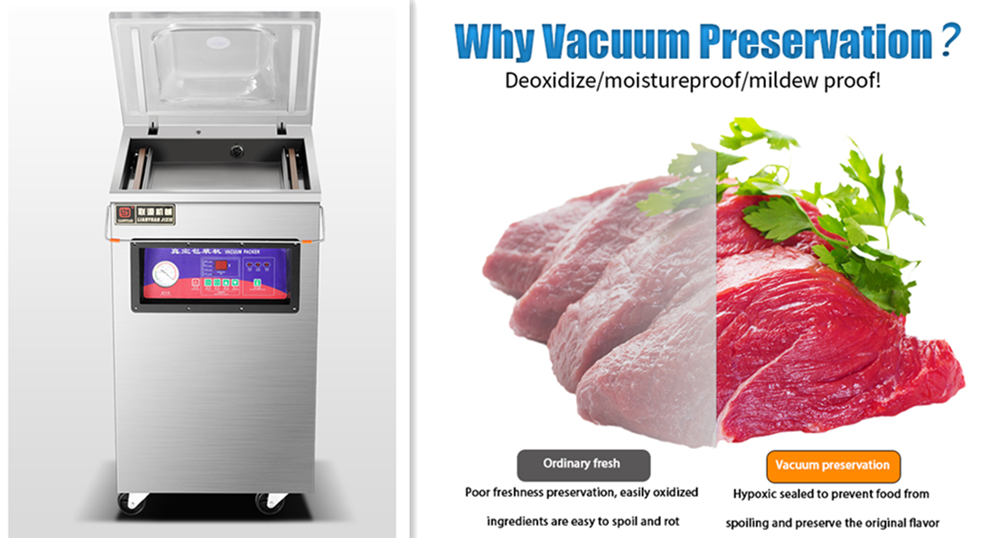

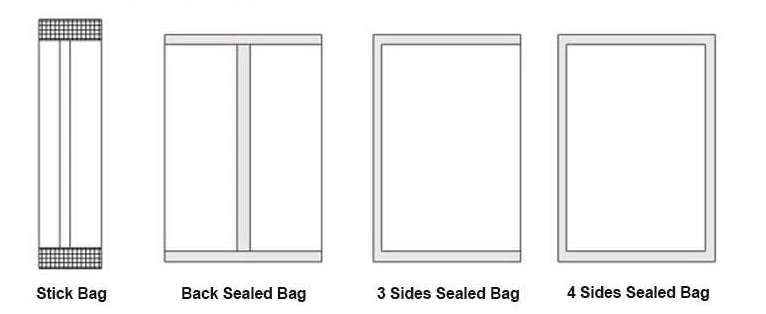

Vacuum packaging is indispensable in today's modern society and it is the most common type of packaging machinery for industrial and food handling applications. Packaging vacuum machine is used for removing air from the package and automatically sealing.

Take Automatic Portable Vacuum Packing Machine as an example.

● Increasing Food store time. Vacuum packing reduces atmospheric oxygen, limiting the growth of aerobic bacteria or fungi, and preventing the evaporation of volatile components.

● Vacuum seals also help control food temperature, further preventing the spoilage of food or discoloring of product

● Heightening display effect. If you use clear film, customers can see the product before they purchasing the product.

●A gas-inflating function are available and smashing can be avoided.

Vertical packing machine includes the process of film running, bags forming, products filling and bag sealing steps. It can be used to pack powder, liquid, tea bag, etc. The vertical machine's automated, assembly-line design is ideal for packing industry professionals. We provide safe and flexible packaging solutions to maximize our clients' cost efficiency.

Take SS-300L Vertical Liquid Packing Machine as an example.

● Function: Feeding, Dosing, Filling, Bag forming, Date print and Sealing all in one.

● Bag dimension: The machine can make sure each bag dimension is very nice.

● Good sealing: Vertical and Horizontal sealing own itself temperature-controller and adjustable. That means bag sealing very well and flexible to film.

● Easy Operation: PLC control, color touch screen, support multiple languages.

● Packing material:BOPP/Polyethylene, Aluminium/Polyethylene, Paper/Polyethylene, Polyester/Aluminized/Polyethylene, Nylon/CPP and so on.

● Safety: The packing machine has multiple level protection: emergency stop button, safety door lock, alarms. All of the touching parts are made of SUS304, which meet food safety grade demand.

Application:

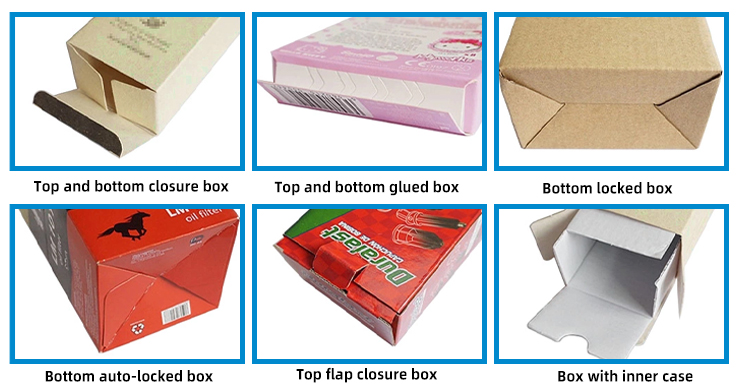

Cartons are one of the most visible and important packaging forms. They are prominent on the shelves of supermarkets and other retailers, and are a key element in logistics of Fast Moving Consumer Goods, handling and product presentation.

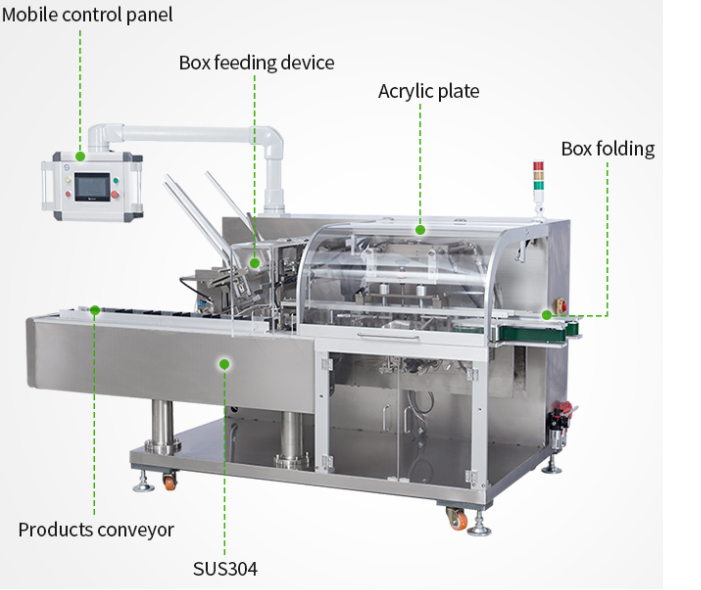

Cartoning machine, sometimes called a cartoner for short, is a type of packaging machine. Cartoning machines or cartoners are packaging systems which erect, close and fill sealed cartons. Cartoning machines can be sub-divided into two basic types: Vertical cartooning machines and Horizontal cartooning machines. A cartoning machine is often used for packaging sundry goods, cosmetics, confectionery, foodstuffs, etc. Take Carton box packing machine SS-120A as an example.

● Auto box feeding, opening, entrying, sealing, waste removing together packing form.Compact and reasonable structure, simple operation and adjustment.

● Servo/stepper motor and touch screen, PLC control system, Man-machine interface display operation would be more clearer and simpler. High degree of automation, more humanized.

● Photoelectric detector automatic detection and tracking system,no feed no packing,the packing material is saved to the maximum extent.

Application:

Sealing machines are packaging machines. It used to close and air seal a product which has been put inside the machine. One of the most common type of sealing machine is the heat sealer, which seals thermoplastics like shrink wrap using the direct application of heat and pressure. Sealing machines are common for food packaging equipment, packaging bakery goods and fresh produce, such as tea bag filling and sealing machine. Sealers are also commonly employed as pharmaceutical packaging equipment for over-the-counter and prescription drug packaging.

Labeling machine can be used for labeling various plastic/glass/metal round cans and bottles with self-adhesive label. This kind of machine is an ideal label equipment that improves the productivity and it is widely used in cosmetic, beverage, food, medicine etc.

Labeling equipment provides the finishing touch to packaging by adding labels for purposes like: product identification, pricing, usage guidance, bar code, shipping instructions and indication of tampering. Labeling equipment can be large enough to tackle high industrial loads, or it can be as small enough for small business purposes, as is the case with a handheld label applicator.

Filling line equipment are designed to fill containers with a certain amount of material, whether it is one large part or a hundred small parts. A popular filler process is “form fill seal”, a process during which the filling machines and equipment takes v-fold or flat material, forms it into a container or bag, and then fills it and seals it. Similar is filling capping sealing, during which bottles are filled, capped and sealed.

Fillers are typically components of conveyors, and their design varies based on whether they are meant to liquid fill or solid fill. Flexible packaging systems like bagging machines work well for liquid packaging. They're often used for storing various chemicals, like solvents and acids, as well as beverages like soda.

►►► Types of filling machines◄◄◄