Stick pack is ideal for today's on-the-go consumers because of its portability, convenience and ease of use. Stick packaging machinery are widely used in various industries today for powder and liquid packaging and they are ideal for many products, such as powdered drink mixes, vitamins & nutritionals, sweeteners.

They do this with a special slitting component that cuts the large roll of packaging film into strips or 'sticks'. After being slit, each stick is formed into a long, thin bag shape, then filled with product, and finally, each stick is sealed shut.

With automatic packing machine able to accommodate up to 20 stick packaging lanes, you can achieve very high throughput with very little floor space, making them a very popular choice for contract packagers. Manufacturers and co-packers love stick pack machines because they achieve high throughput and conserve valuable plant floor space.

But how does this equipment work? In today's article, we will tell you how a stick pack machine turns a single roll of film into multiple shelf-ready packages.

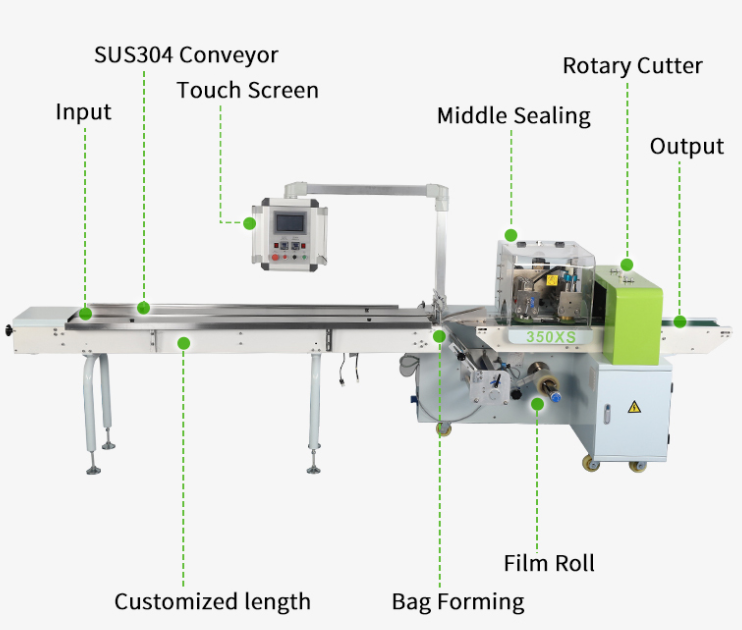

Full ServoHorizontal Packing Machine China SS-350XS/450XS

● All control in onetouch screen, user-friendly andeasy operation

● Empty bag prevention, no product no bag

● Product cutting prevention, machine will stop once cutter cuts the product

● Memory function, can store99 groups of package parameters (product position, packing speed, bag length)

● No limit for product length

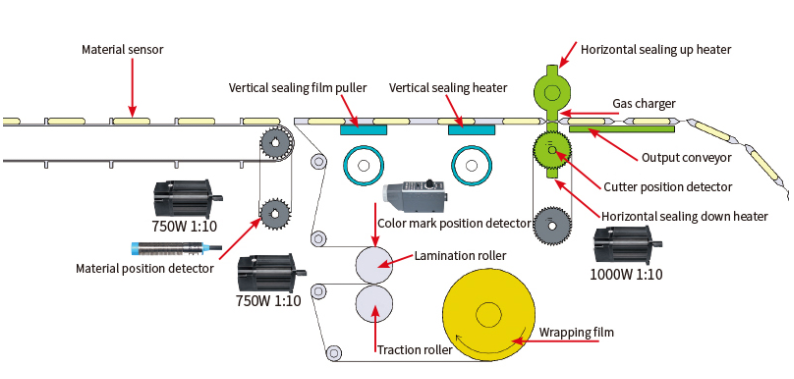

The stick packaging machine use a piece of film rolled around a rollstock, and then the film is unwound from the film reel, positioned at the rear part of the machine. The film unwinding process is done by means of movement of the cross seal jaws, located at the front of the stick packingmachine.

If the packing machine is equipped with a date-stamping device, the film is fed around a registration roller. The film is threaded over a sensor that reads eye marks and controls the position of the horizontal seal in relation to the printing on the film.

Next, the film is fed through a set of nip rollers. The nip rollers keep even pressure on the film to help to keep it at a constant tension, thus keeping the dancer arm in the proper operating position.

During unwinding, the film is unwound from the roll and passes over a dancer arm which is a weighted pivot arm located at the rear of the machine. The arm incorporates a series of rollers. As the film transports, the arm moves up and down to keep the film under tension while also ensuring the film will not wander from side to side as it is moving.

From the nip rollers, the film goes into the cutting section. During this step in the process, the large roll of packaging film is cut into strips based on how many lanes the stick pack machine has. These strips form the basis for the individual stick packs.

The cutting disk knives that complete this step are not motorized. The film, still kept under tension, is passed through the knives which are in contact with a specially designed roller. The film is cut into individual stick packs as it is pulled through this assembly.

From here, the cut film passes over multiple forming tubes. As the cut film crests the shoulder on each forming tube, it is folded around the tube so that the end result is a stick pack shape with the two outer edges of the film overlapping each other.

The hot vertical sealer bars will move forward once the film stops moving, so as to make contact with the vertical overlap on the film. The vertical seal bar presses itself against the forming tube and makes the vertical seal.

The product has been released into each stick pack and the knife cuts the bag. Then the finished stick packs drop into the outfeed chute. Last but not least, the bags can be fed into downline equipment, such ascartoning machine or check weighers.

In the end, purchasing the stick granule packing machine means taking your time to research your options and to learn as much as you can about the products that are available. In doing so, you will be able to nail down all the details and weigh the pros and cons of each.