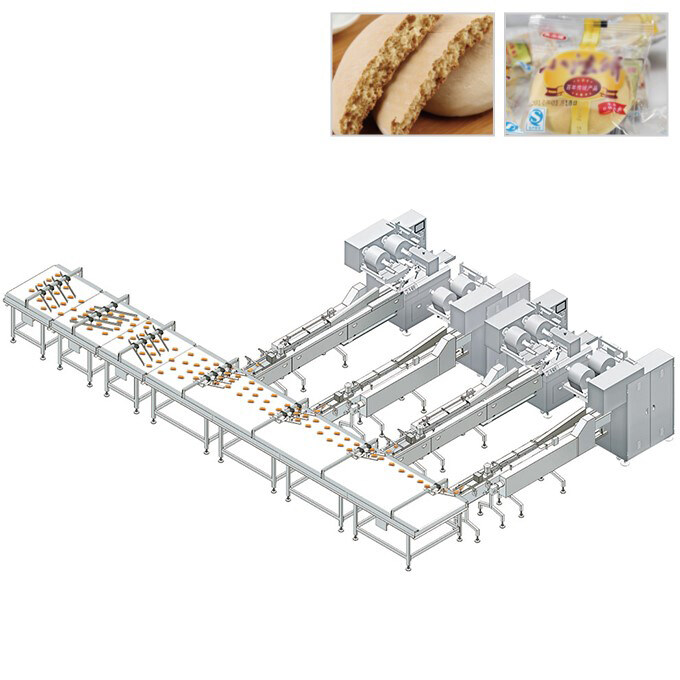

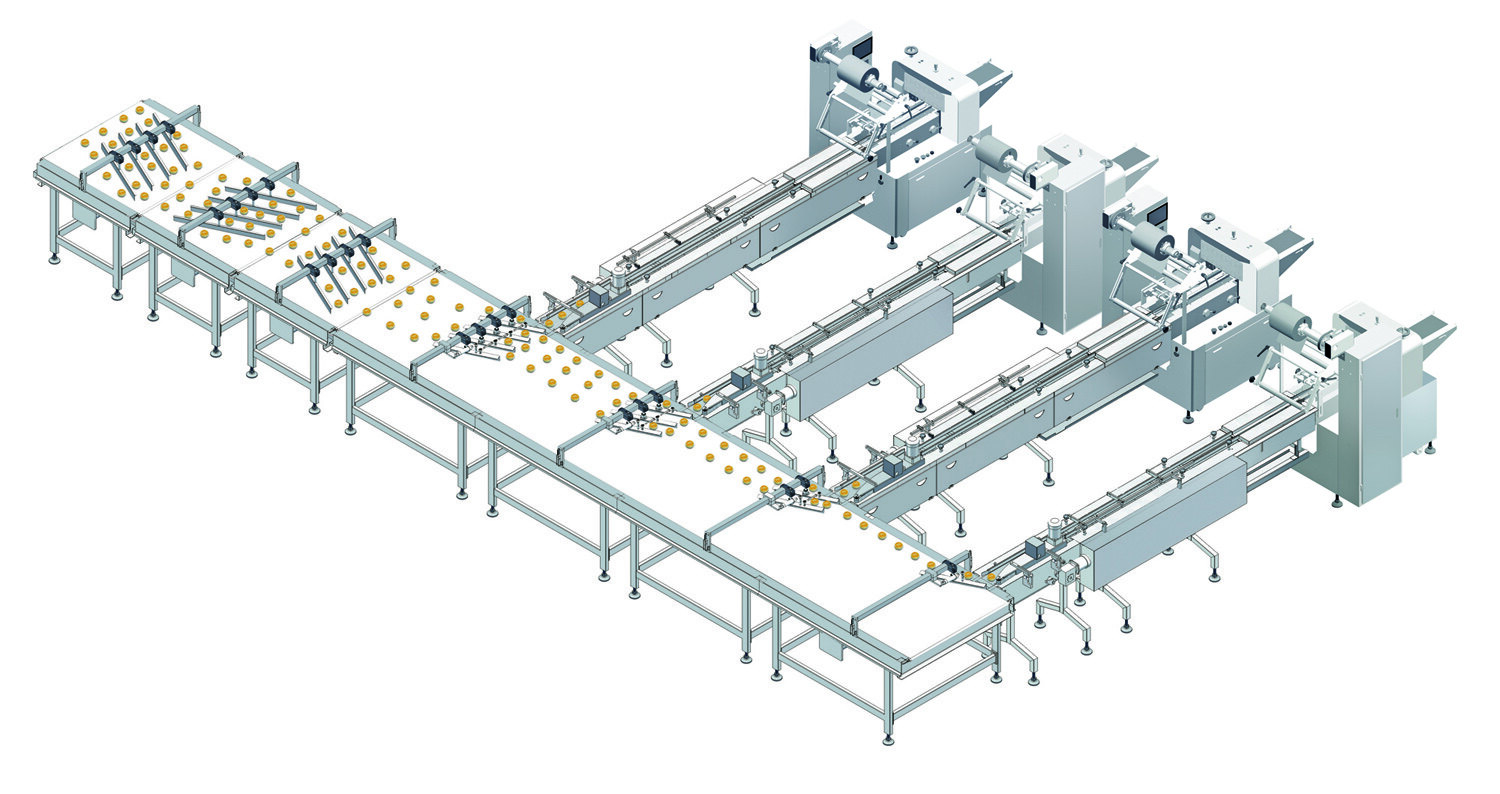

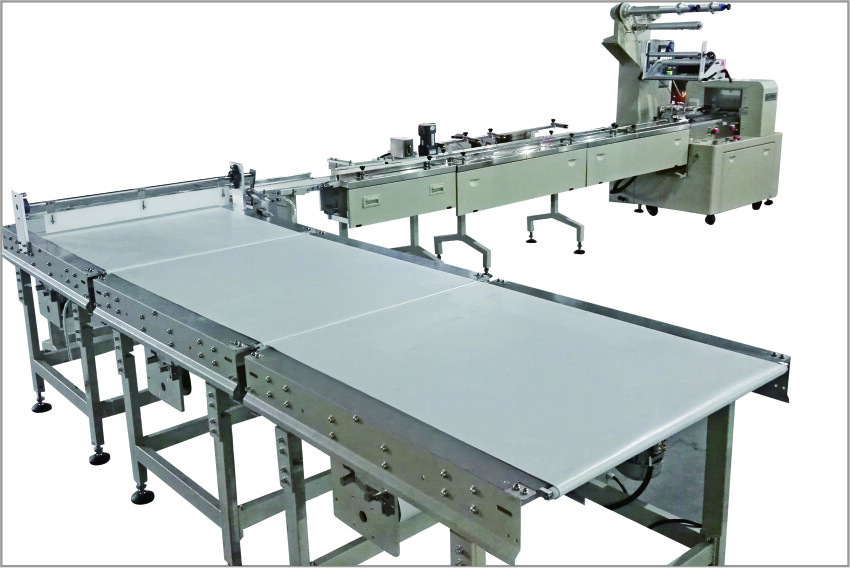

1. Clear-up, feeding and packing automatically without man-powder operation.csiga noodles packing line

2. Clear-up machine and positioning feeding machine can be operated separately. They can work in synchronization with producing line, synchronous change speed, automatic stop/startup in case of material absence/supply and so on.

3. Adopt multi-variable frequency speed control, servo drives control, easy operation, stable running, high of control preciseness,low energy consumption.

4. To minimize secondary pollution of produts due to traditional manpower arrangement.

5. Clear-up correctly and the speed is up to 200 bags/min with high efficiency.

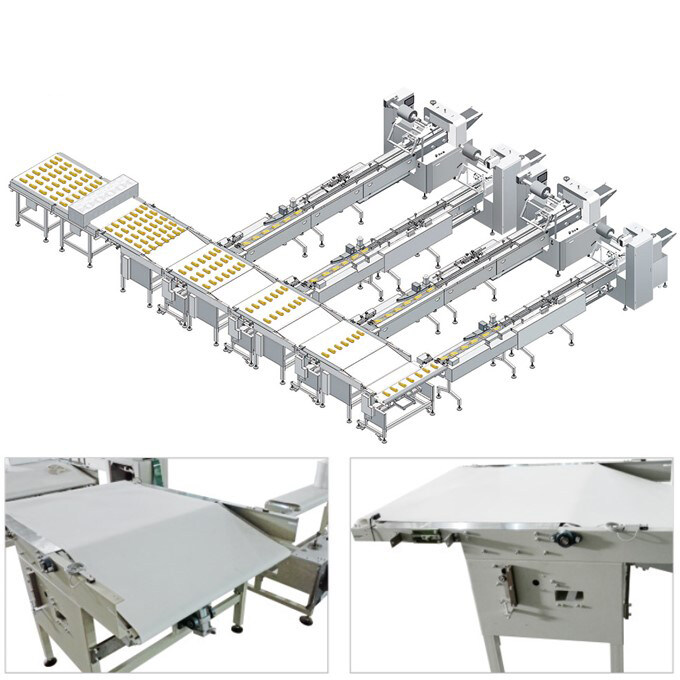

6. Simple frame, easy maintenance, all conveyor belts can be detached quickly without using any tool, ensuring food safe and healthy.

| Model | SS-BPS | ||||||

Product name |

Automatic Feeding & packaging line | ||||||

Product size |

9000×950×1500 mm (According to the actual situation) |

||||||

| Weight | Customized | ||||||

Master conveyor belt width |

600/800/1000/1200 mm | ||||||

Packing capacity |

50-200 bags/min (per single lane) | ||||||

Power supply |

1ph-220V-50Hz or 3 ph-380V-50Hz | ||||||

Total power |

To be finalized according to user's actual situation | ||||||

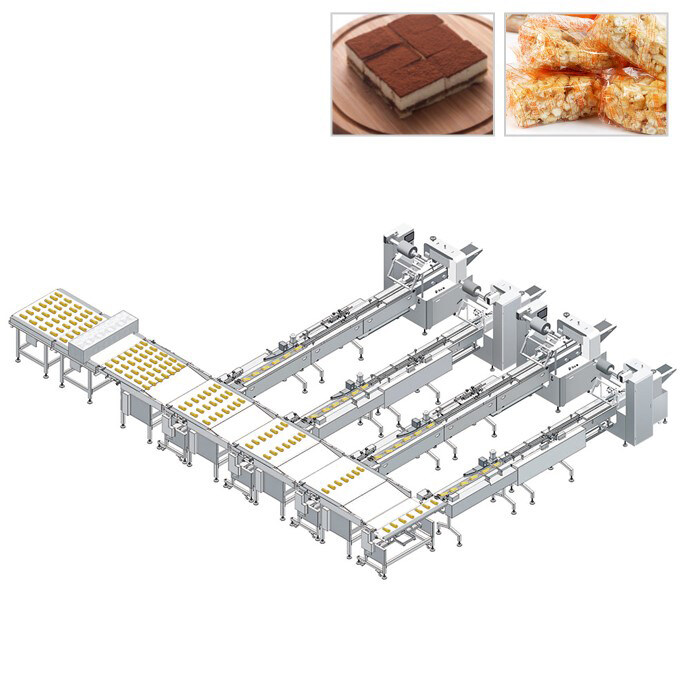

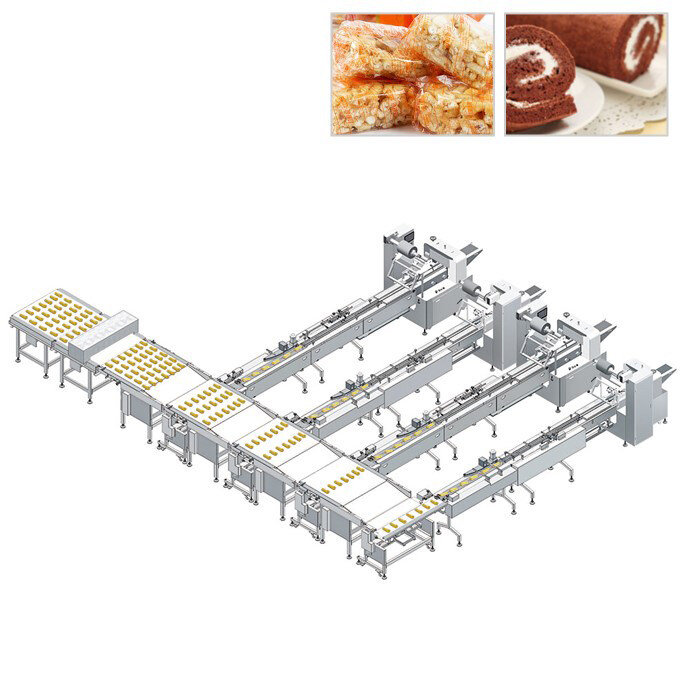

Application Fields |

Breads, Biscuits, Cakes, Waffles, Chocolates, Noodles | ||||||

Main Performance And Structure Features |

1. Clear-up, feeding and packing automatically without man-powder operation. 2. Clear-up machine and positioning feeding machine can be operated separately. They can work in synchronization with producing line, synchronous change speed, automatic stop/startup in case of material absence/supply and so on. 3. Adopt multi-variable frequency speed control, servo drives control, easy operation, stable running, high of control preciseness,low energy consumption. 4. To minimize secondary pollution of produts due to traditional manpower arrangement. 5. Clear-up correctly and the speed is up to 200 bags/min with high efficiency. 6. Simple frame, easy maintenance, all conveyor belts can be detached quickly without using any tool, ensuring food safe and healthy. |

||||||

1. Food Box Packing Machine

2. Food Powder Packing Machine

3. Liquid Packing Machine

4. Tea Bag Packing Machine

5. Instant Noodles Packaging Machine

6. Skin Packaging Machine For Food

7. Food Wrapping Machine

1. Vertical Vacuum Packing Machine

2. Double Chamber Vacuum Packing Machine

3. Powder Vacuum Packing Machine

4. Vacuum Skin Packing Machine

1. Vertical Pouch Packing Machine

2. Vertical Powder Packing Machine

3. Vertical Liquid Packing Machine

4. Vertical Cartoning Machine

5. Vertical Packing Sealing Machine

1. Automatic Cartoning Machine

2. Automatic Box Packing Machine

3. Automatic Vacuum Packing Machine

4. Automatic Vertical Packing Machine

5. Automatic Double Chamber Vacuum Packing Machine

6. Automatic Powder Packing Machine

7. Automatic Granule Packing Machine

8. Automatic Instant Noodles Packaging Machine

9. Automatic Food Wrapping Machines

10. Automatic Skin Packaging Machine

11. Automatic Food Packing Machine

| Model | SS-BPS | ||||||

Product name |

Automatic Feeding & packaging line | ||||||

Product size |

9000×950×1500 mm (According to the actual situation) |

||||||

| Weight | Customized | ||||||

Master conveyor belt width |

600/800/1000/1200 mm | ||||||

Packing capacity |

50-200 bags/min (per single lane) | ||||||

Power supply |

1ph-220V-50Hz or 3 ph-380V-50Hz | ||||||

Total power |

To be finalized according to user's actual situation | ||||||

Application Fields |

Breads, Biscuits, Cakes, Waffles, Chocolates, Noodles | ||||||

Main Performance And Structure Features |

1. Clear-up, feeding and packing automatically without man-powder operation. 2. Clear-up machine and positioning feeding machine can be operated separately. They can work in synchronization with producing line, synchronous change speed, automatic stop/startup in case of material absence/supply and so on. 3. Adopt multi-variable frequency speed control, servo drives control, easy operation, stable running, high of control preciseness,low energy consumption. 4. To minimize secondary pollution of produts due to traditional manpower arrangement. 5. Clear-up correctly and the speed is up to 200 bags/min with high efficiency. 6. Simple frame, easy maintenance, all conveyor belts can be detached quickly without using any tool, ensuring food safe and healthy. |

||||||