Granule packing machines are widely used in various industries, including food, pharmaceuticals, and chemical production. These machines are designed to accurately measure and package granular materials, such as grains, nuts, seeds, and powders.

There are several types of granule packing machines available on the market, including:

● Vertical granule packaging machine

● Horizontal granule packaging machine

● Pre-made pouch machines

Granule packing machines come with a variety of features that can enhance their functionality and efficiency. Some of these features include:

● Automatic or manual operation

Some granule packing machines are fully automated, while others require manual operation.

● Multi-head weighing

This feature allows the machine to measure and dispense multiple products simultaneously.

● Touchscreen interface

A user-friendly touchscreen interface can make it easier to operate the machine and make adjustments.

● Adjustable bag size

The machine should be able to accommodate various bag sizes to meet your packaging needs.

There are several advantages to using granule packing machines in your production line, including:

● Improved accuracy

Granule packing machines can accurately measure and dispense the correct amount of product for each bag.

● Increased productivity

With a granule packing machine, you can pack products at a faster rate than manual packaging.

● Consistency

Granule packing machines can ensure that each bag is filled with the same amount of product, resulting in consistent product quality.

● Cost-effective

Using a granule packing machine can reduce labor costs associated with manual packaging.

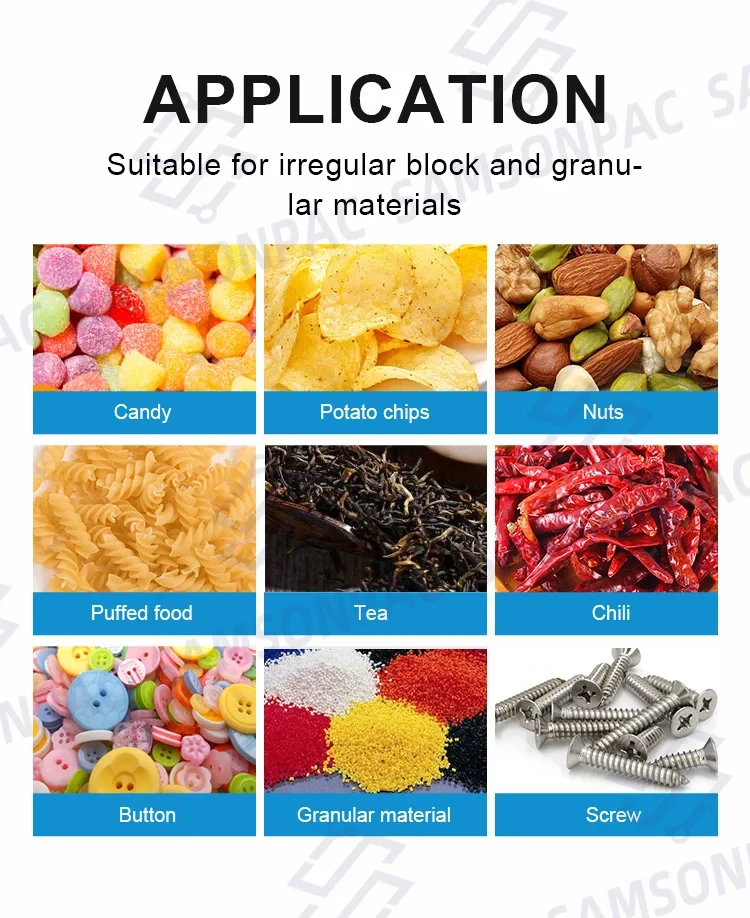

Granule packing machines have a wide range of applications in various industries, including:

● Food industry

Granule packing machines are used to package various food products, including grains, nuts, seeds, and spices.

● Pharmaceutical industry

These machines are used to package pills, capsules, and other solid medications.

● Chemical industry

Granule packing machines are used to package various chemicals, such as fertilizers and pesticides.

● Pet food industry

These machines are used to package various pet food products, including dry food and treats.

Proper maintenance of granule packing machines is essential to ensure their optimal performance and longevity. Some maintenance tasks include:

● Regular cleaning

The machine should be cleaned regularly to prevent the buildup of product residue and debris.

● Lubrication

The moving parts of the machine should be lubricated regularly to reduce wear and tear.

● Calibration

The machine should be calibrated regularly to ensure that it is accurately measuring and dispensing the correct amount of product.

● Replacement of worn parts

Any worn or damaged parts should be replaced promptly to prevent further damage to the machine.

Granule packing machines are a valuable asset to any production line, offering improved accuracy, consistency, and productivity. When choosing a granule packing machine, it is important to consider your specific packaging needs and the features that will best meet those needs. Proper maintenance and upkeep of the machine will ensure its optimal performance and longevity, resulting in a cost-effective and efficient packaging process.