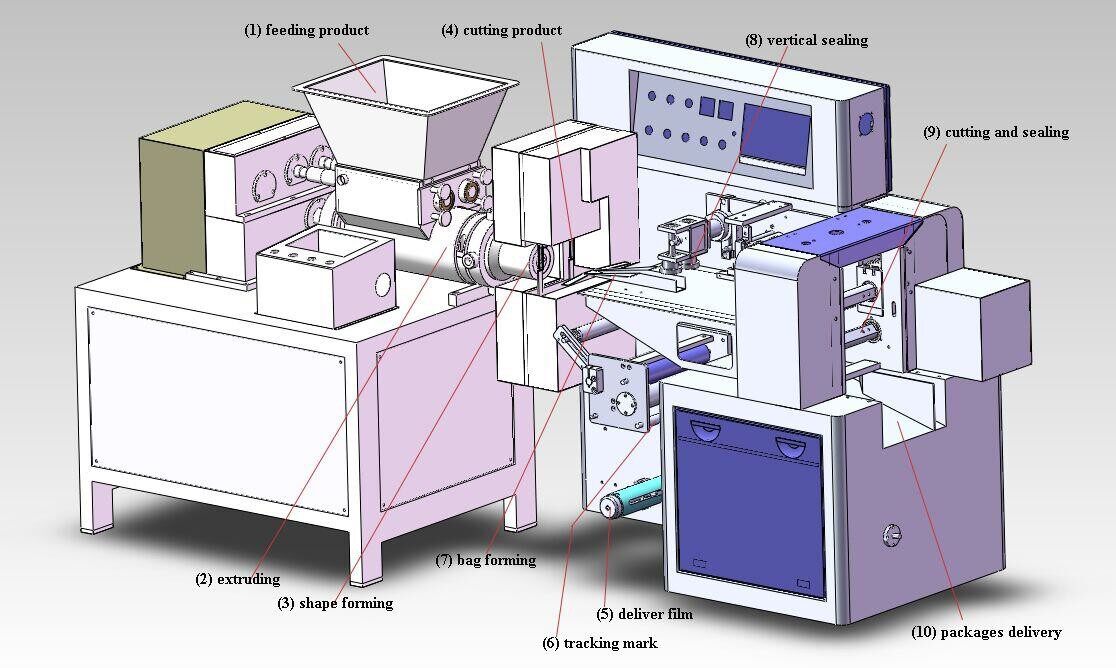

① feeding product: to feed the products manually into the exturder hopper.

② Extruding: extrude the products.

③ Shape forming: shaping the products by kinds of molds.

④ Cutting product: to cut the extruded product by set length.

⑤ Deliver film: to let the packing film run into the bag former smoothly.

⑥ Tracking mark: to track the film’s color marks by a sensor and let the machine cut the correct bag length.

⑦ Bag forming: to form the film into a bag by the bag former. It’s adjustable to fit for different product sizes.

⑧ Vertical sealing:to clamp and seal the vertical sealing.

⑨ Cutting and sealing: to seal the end sealing and cut the bag. Can make round hole or euro hole on the package.

⑩ Packages delivery: convey the finished packages.

Special features:

Full automatic production line with 2 in 1 functions( extruding and packing functions)

Reduce manual operation and avoid touching products, no pollution and deformation

Easy operation and clean

High speed for cutting and packing

Accurate length cutting

Stable performance

With patent

Easy operation and clean

Use different cutting knife for different product

2 touch screens (extruder & packing machine) for convenient operation

Fit for different product length (CB-350SXL - servo version)

|

Output |

Up to 150 products per minute Up to 30 m/min film speed Product and film characteristic may affect machine output |

|

Size Range |

|

|

Package cut-off length |

60-200mm |

|

Product width |

max.165mm |

|

Product height |

max.60mm |

|

Packaging Material Reel |

|

|

Reel diameter |

≤300mm |

|

Core diameter |

≤75mm |

|

Packaging material width |

max.350mm |

|

Weight |

max. 25KG |

|

Connections |

|

|

Voltage |

380V,50HZ |

|

Power usage |

7KW |

|

Machine weight |

1100kg |

|

Machine dimensions |

L2350XW1000XH1350mm |

|

Blade cut type |

Rotary cutter |